They represent a percentage or rate that is applied to an appropriate cost driver, such as labor hours or machine hours, to assign overhead costs to products. Before the start of the year, you calculate your total estimated manufacturing overhead costs. These might include things like indirect labor, indirect materials, utilities, rent, and depreciation on your factory machines – costs which are difficult to attribute directly to individual products.

Step 2: Pick Your Allocation Base

According to a survey 34% of the manufacturing businesses use a single plant wide overhead rate, 44% use multiple overhead rates and rest of the companies use activity based costing (ABC) system. Applying our formula, we get $188,000 in fixed overhead divided by the base of 18,800 total direct labor hours for an allocation rate of $10 per labor hour. If SailRite produces 2,000 units of the Deluxe boat, will the unit cost remain at $5,030? A significant portion of overhead costs are fixed and will be spread out over more units, thereby reducing the cost per unit. The point here is that managers must beware of using per unit cost information blindly for decision making, particularly if a significant change in the level of production is anticipated.

- The comparison of applied and actual overhead gives us the amount of over or under-applied overhead during the period which is eliminated through recording appropriate journal entries at the end of the period.

- If overhead costs rise rapidly, increasing overhead rates will make this clear.

- Hence, preliminary, company A could be the winner of the auction even though the labor hour used by company B is less, and units produced more only because its overhead rate is more than that of company A.

- This $4 per DLH rate would then be used to apply overhead to production in the accounting period.

- A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs.

- Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs.

Calculating Overhead Cost Per Unit

As your business grows and becomes more complex, you can refine your methodology. Remember, even a rough predetermined rate is better than ignoring overhead entirely, which is a common mistake that leads to underpricing and cash flow problems. Applying our formula, we get $188,000 in fixed overhead divided by the base of 47,000 total direct machine hours for an allocation rate of $4 per machine hour. At this point, we have identified the most important and costly activities required to make products, and we have assigned overhead costs to each of these activities. The next step is to find an allocation base that drives the cost of each activity. If Department B has overhead costs of $30,000 but direct costs of $70,000, then its overhead rate is 43%.

Predetermined Overhead Rate Calculation (Step by Step)

Therefore, the one with the lower shall be awarded the auction winner since this project would involve more overheads. Enhance your proficiency in Excel and automation tools to streamline financial planning processes. Learn through predetermined overhead rate formula real-world case studies and gain insights into the role of FP&A in mergers, acquisitions, and investment strategies.

How to calculate the predetermined overhead rate: Example 3

The use of multiple predetermined overhead rates may be a complex and time consuming task but is considered a more accurate approach than applying only a single plant-wide rate. We have discussed three different methods of allocating overhead to products—plantwide allocation, department allocation, and activity-based costing. Remember, total overhead costs will not change in the short run, but the way total overhead costs are allocated to products will change depending on the method used. One of the advantages of predetermined overhead rate is that businesses can use it to help with closing their books more quickly. This is because using this rate allows them to avoid compiling actual overhead costs as part of their closing process. Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal year.

- The next step is to find an allocation base that drives the cost of each activity.

- Various activity and cost bases can be used, including direct labor hours, machine hours, and production units.

- The computation of the overhead cost per unit for all of the products is shown in Figure 6.4.

- Understanding how to calculate this rate ensures accurate cost estimation, leading to better decision-making and profitability.

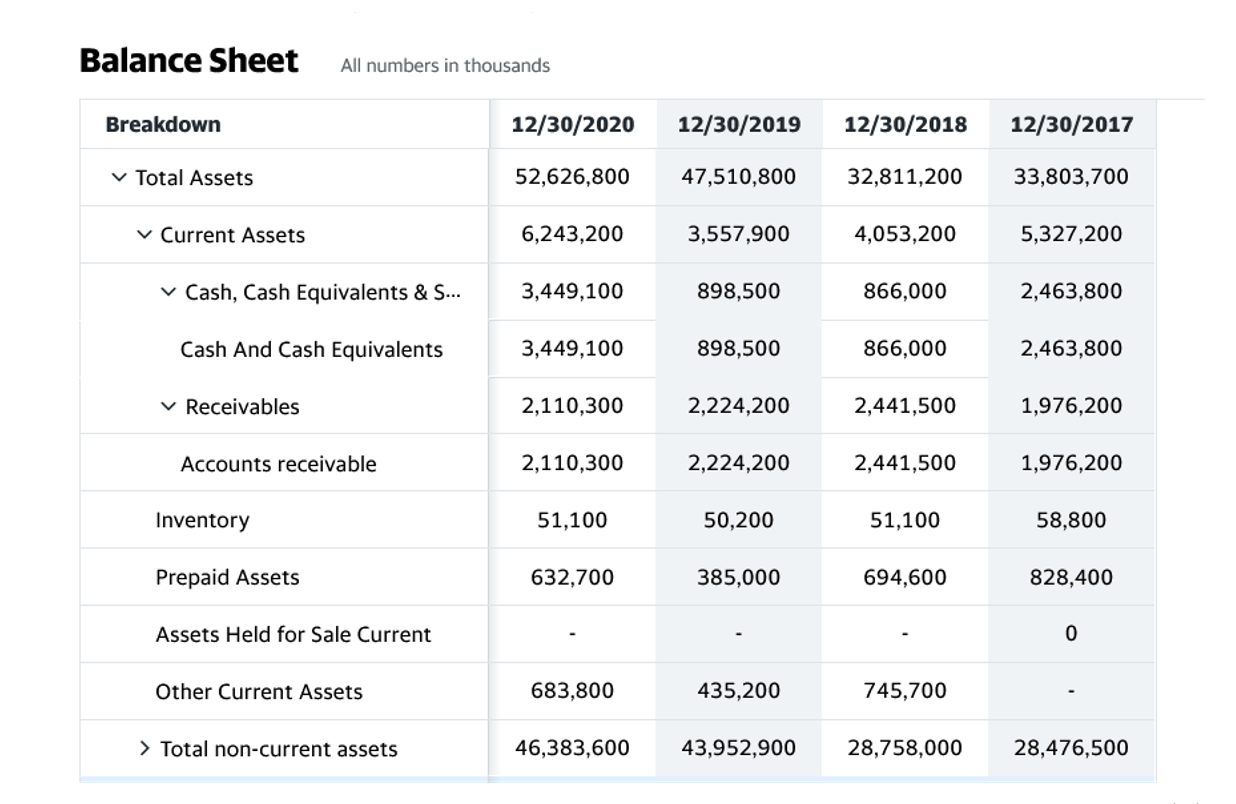

With 150,000 units, the direct material cost is trial balance $525,000; the direct labor cost is $1,500,000; and the manufacturing overhead applied is $750,000 for a total Cost of Goods Sold of $2,775,000. Detailed analysis of predetermined overhead rates helps businesses identify the activities or factors that drive overhead costs, enabling targeted cost-reduction measures. To calculate a predetermined overhead rate for mixed costs, the fixed and variable portions must be separated. The fixed portion is allocated using a fixed allocation base, and the variable portion is assigned based on an activity measure. To allocate overhead costs to production departments, the predetermined overhead rate is multiplied by the actual activity level in each department.

Methods used for activity-based costing

This can lead to more informed decision-making about pricing and production levels. E-commerce businesses typically have different overhead structures – they might have higher technology and website maintenance costs but lower physical store expenses. The cost information provided by ABC is generally regarded as more accurate than the information provided by most traditional costing methods. Notice that this information includes an estimate of the levelof activity for each cost driver, which is needed to calculate apredetermined rate for each activity in step 4. Carefully minimizing overhead is crucial for small businesses to maintain profitability.

Table 9.2 illustrates the various cost pools along with their activities and related costs. It is used in cost accounting to estimate manufacturing overhead costs for a specific period. A cost pool is a list of costs incurred when related activities are performed. Table 6.3.1 illustrates the various cost pools along with their activities and related costs. Analysis More overhead is allocated to the lower volume mountain bicycles using activity-based costing.

How do you calculate predetermined overhead rate in accounting?

After reviewing the product cost Accounts Payable Management and consulting with the marketing department, the sales prices were set. The sales price, cost of each product, and resulting gross profit are shown in Figure 6.6. For example, the activity driver for the setup activity might be the number of setups that are performed. The activity driver for the production activity might be the number of units that are produced. This depends on the size and complexity of your business, but a good rule of thumb is to strike a balance between accuracy and practicality.